FusionKnits is a professional clothing manufacturer based in China, working with global brands to produce high-quality apparel. We support production from sampling to bulk orders, with flexible capacity, reliable quality control, and clear communication.

We work closely with clothing brands, buyers, and designers, focusing on stable production, consistent quality, and reliable delivery for long-term cooperation.

FusionKnits provides end-to-end clothing manufacturing services, supporting brands at different stages of product development and production. Our focus is on reliable execution, flexible capacity, and long-term manufacturing partnerships.

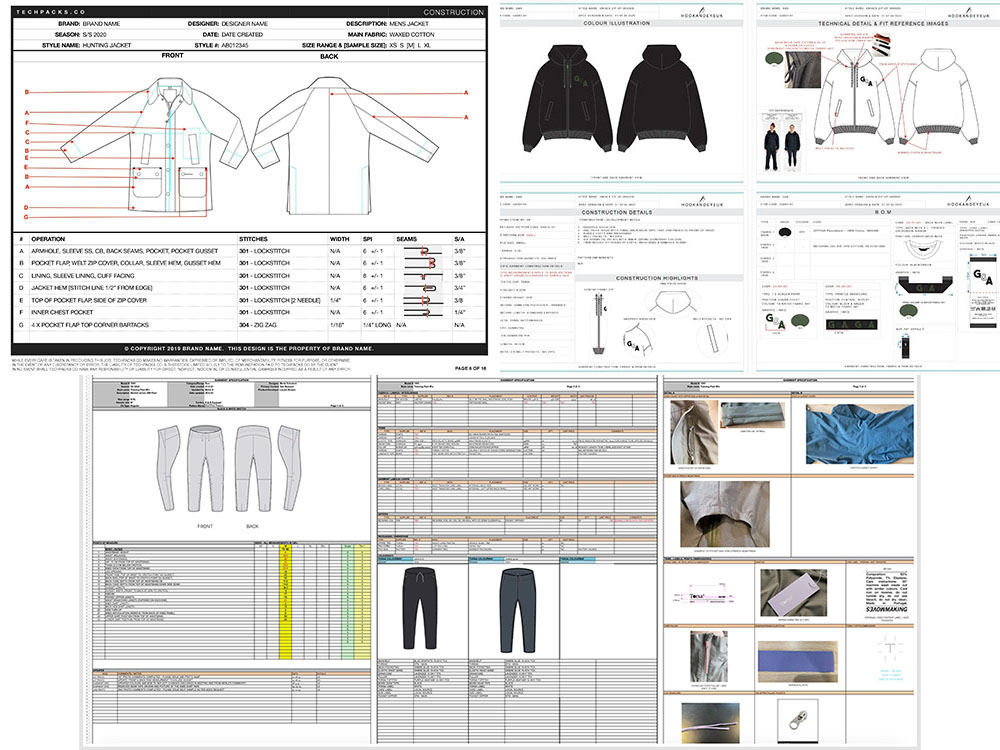

Professional production of apparel based on confirmed designs and specifications.

Manufacturing solutions tailored to brands with ready designs or development needs.

Sampling support to test fit, materials, and construction before bulk production.

Flexible production options for both trial orders and large-scale manufacturing.

Structured inspection processes to ensure consistent quality throughout production.

Production prepared for international shipment with clear documentation and coordination.

Our manufacturing capabilities cover a wide range of core clothing categories commonly used in casual, active, and lifestyle collections. These categories represent the types of apparel we regularly produce for global brands.

From concept to finished garments, we help brands transform designs into well-executed clothing with stable production and consistent quality.

As a clothing manufacturer, our strengths are built around stable production, clear processes, and dependable execution. We focus on long-term cooperation rather than short-term orders.

We follow a structured manufacturing workflow to keep product development, production, and delivery clear and controlled at every stage.

We review your tech pack, measurements, materials, and workmanship requirements to confirm production feasibility.

We provide a quotation and propose a production plan based on your order quantity, timeline, and specification needs.

Samples are developed to confirm fit, construction details, and overall product execution before bulk production.

Final adjustments are confirmed and approved to lock specifications, materials, and key details for production.

Bulk production starts with in-line checks to ensure consistent workmanship, measurements, and quality standards.

Finished garments are inspected, packed, and prepared for export shipment with coordinated delivery arrangements.

Our factory and team form the foundation of our manufacturing capabilities. From production floors to quality inspection and on-site coordination, we focus on controlled processes, skilled execution, and reliable teamwork.

生产线 / 车间环境

成衣制作与工序细节

质检 / 包装环节

团队协作或现场会议

展会或客户接待场景